Antenna Products Engineering

Our engineering staff is highly qualified and has a broad base of experience in the design of antennas, transmission systems, tower structures, and related accessories. This experience base can be applied to transform the most rigorous requirements into cost-effective, highly reliable design solutions.

Antenna Products has a rapidly growing list of satisfied customers that have required unique solutions for their specific antenna deployments, further evidence of our industry-leading design capability. The Quality system at Antenna Products Corp is in compliance with ISO 9001:2015. The design process is monitored through design reviews and performance testing to ensure the design complies with customer requirements.

Antenna Products will gladly provide a proposal to manufacture to customer drawings and/or specifications. We have a dedicated staff to help customers with engineering or manufacturing using the latest techniques. Contact us here for more information, or call us at 940-325-3301

Antenna Design and Performance

The design and performance specifications of our antennas are developed and verified using theoretical analysis and scale modeling techniques. Theoretical RF analysis is conducted using the following computer software and hardware:

- Method of Moments Electromagnetic Scattering Program (ESP)

- Numerical Electromagnetics Code, (NEC-2 AND -3)

- Uniform Geometrical Theory of Diffraction Reflector Antenna Code

- Propagation System Analysis, Ion-Cap

- Ground Screen Analysis

- GEMACS

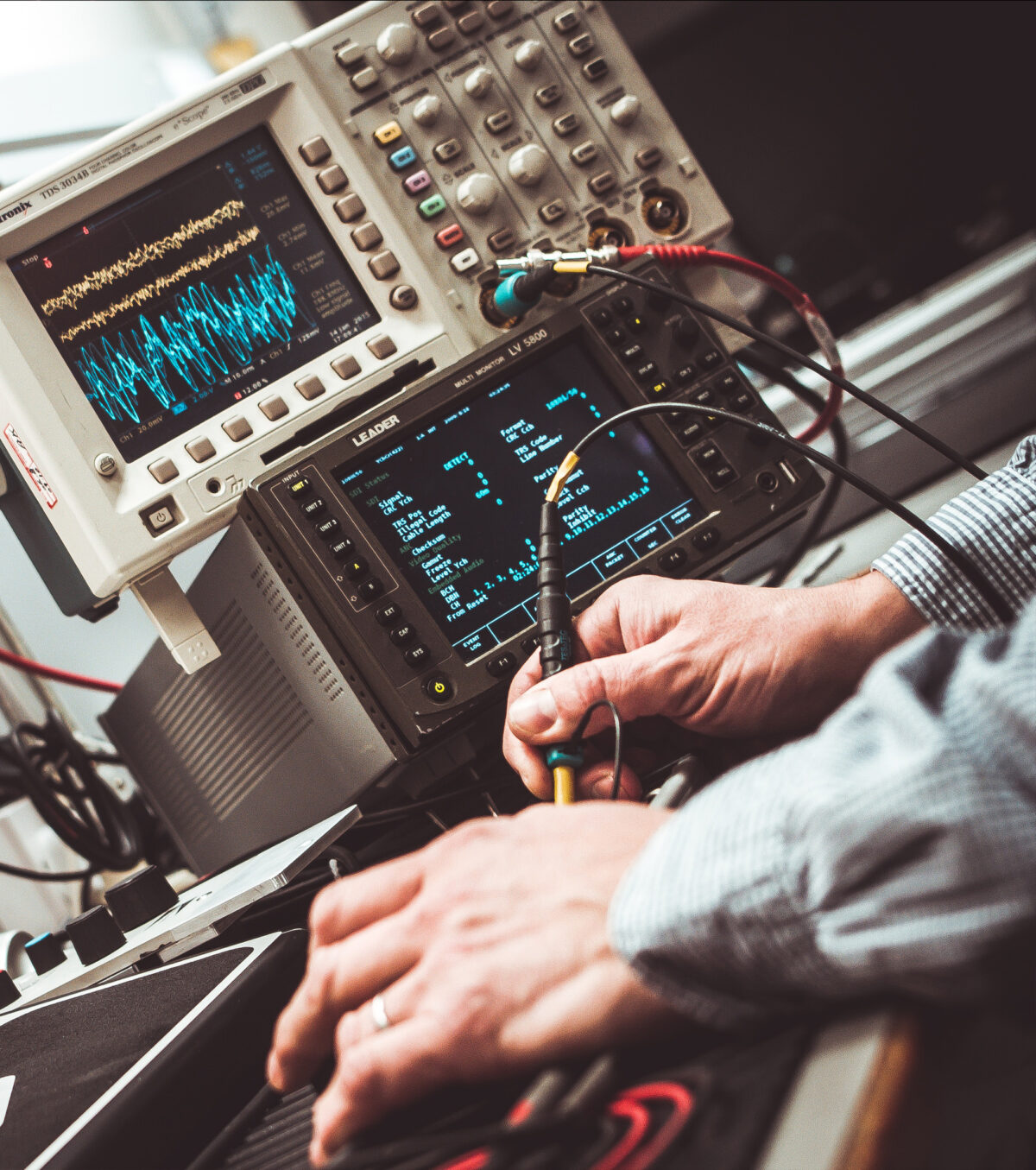

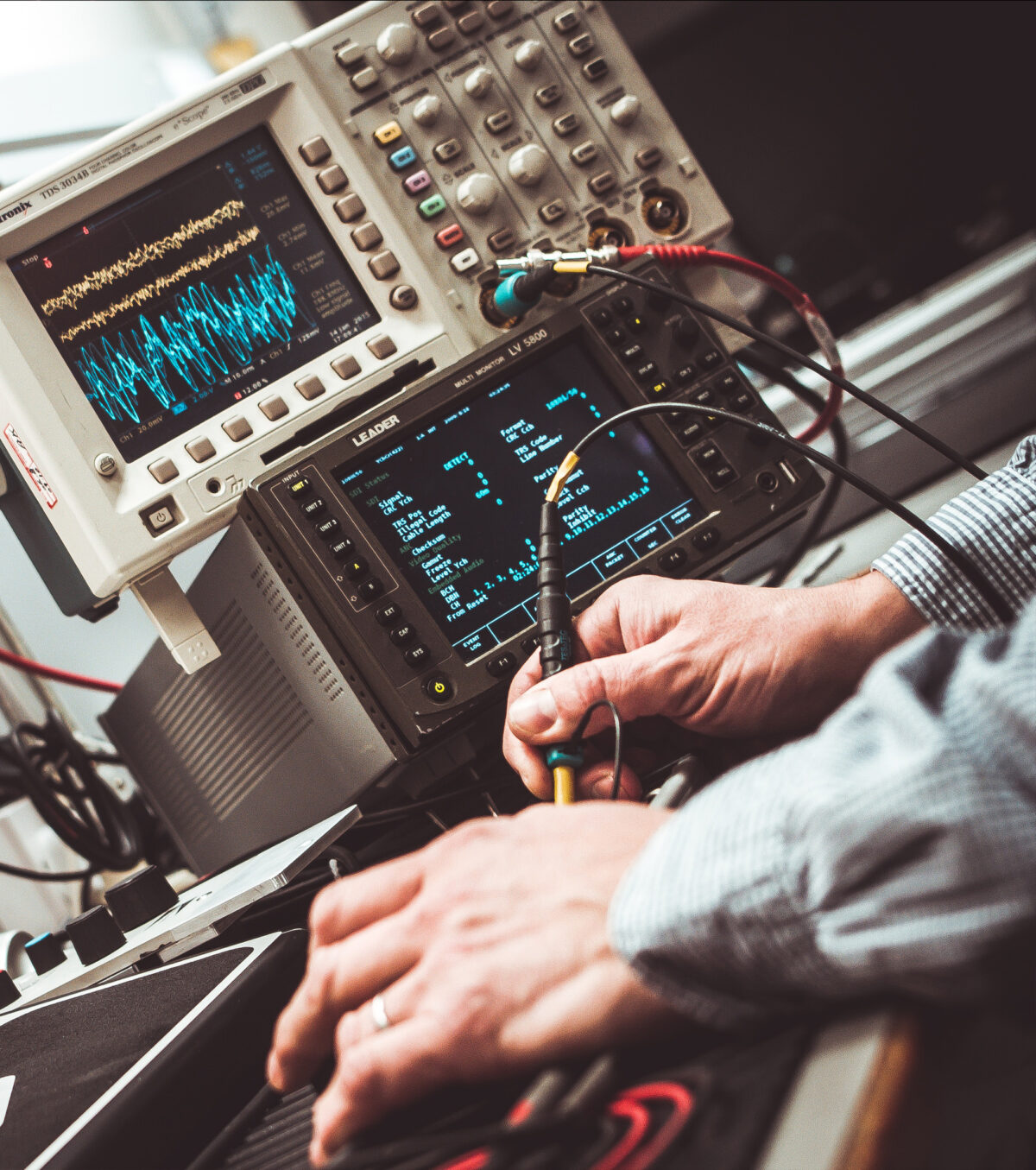

Testing

Antenna radiation pattern and gain performance testing on scale model to full size antennas are conducted at our fifty acre test site and far field pattern range. HF antenna designs are full power tested up to 10 kW and insulators are tested for voltage breakdown up to 50 kV using an HF cavity.

Structural Analysis

Our engineers conduct structural analysis using finite element techniques, computer modeling and classical analysis techniques to design and optimize antenna systems, towers and other support equipment such as rotational drive systems and electrical winch assemblies. The Company designs foundations and anchors and performs site surveys as required for unique installation requirements. Structural analysis programs used at Antenna Products include:

- ODLEY Tower 12 and Tower 14: Tall Guyed Tower Analysis

- ANSYS: Static and Dynamic Finite Element Analysis

- SAP 90: Finite Elements Analysis

- Pro/Engineering Solid Modeling Software

Environmental Testing

The full range of MIL-STD-810 Environmental Testing is also within our capabilities, with access to some of the largest test chambers available. Test capabilities include High and Low Temperature, Salt Fog, Humidity, UV Exposure, Altitude Simulation, Vibration, Shock, Rain and Temperature-Altitude. Load testing of antenna insulators and insulator clusters up to 230,000 pounds is conducted using a tensile testing machine on samples up to 50 feet in length. Antenna Products also maintains a shock test table that is qualified to US Navy standards outlined in MIL-S-901 for lightweight equipment.

Safety

Our products are designed to be safe, highly reliable and easily maintained. This philosophy applies to both internally and externally funded development programs. Our engineering and quality assurance departments can provide reliability and maintainability predictions and safety assessments to meet customer specific program requirements. Our engineering and support staff have extensive experience conducting complete Reliability, Maintainability, Safety and Human Factors Programs.

Documentation

Our engineering documentation is prepared in accordance with DOD Standards 100 and 1000. Configuration control practices are in accordance with MIL-STD-483. Orthographic production drawings are produced and plotted on a multi-station CAD System and diazo process copies in blueline and mylar are available. We can also provide military and commercial technical manuals, together with illustrated parts breakdowns, illustrated drawings, maintenance schedules, bills of materials, and packing lists as needed.